Kendrion Holding Magnets

Browse Kendrion Holding Magnets by type

-

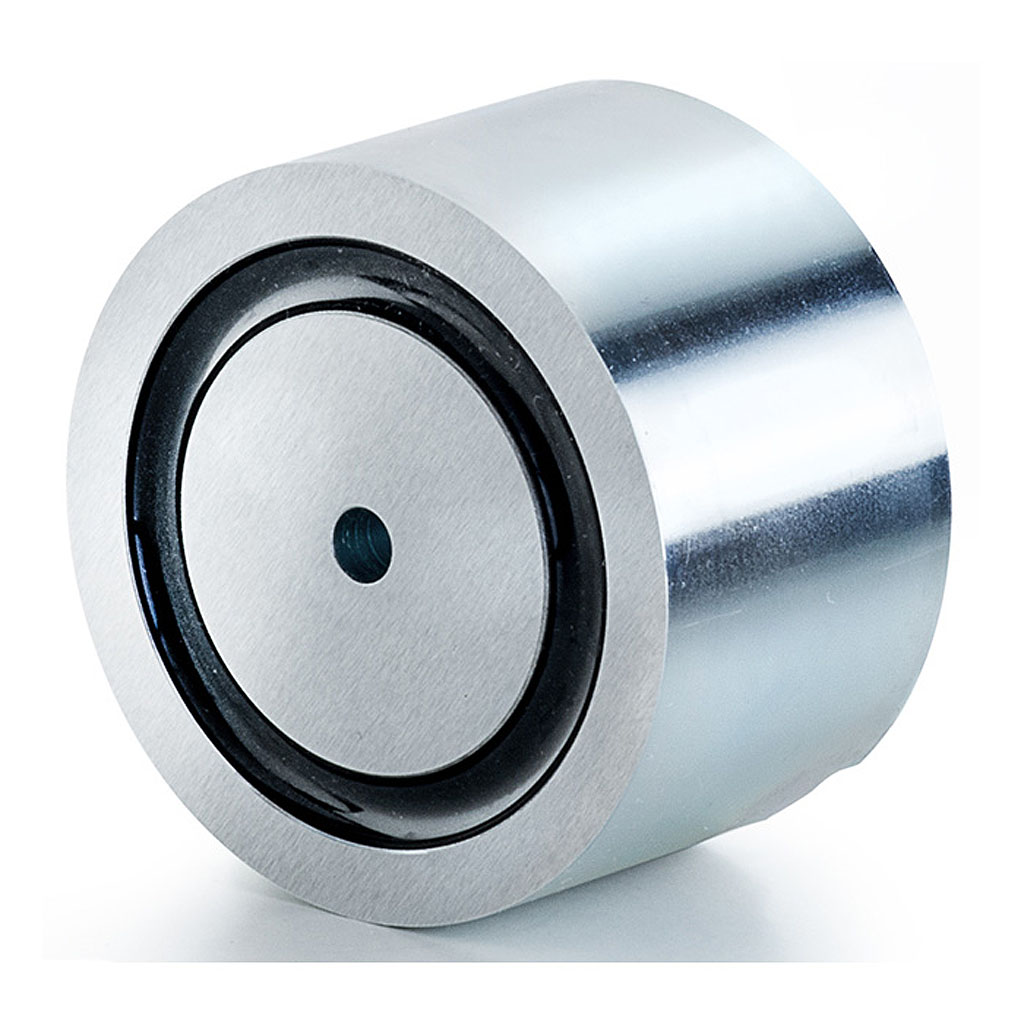

GTB Electro Holding Magnet

- Compact round shaped body.

- Energised holding force.

- 14 body sizes.

- Up to 30,000N holding force.

-

GTH Electro Holding Magnet

- Compact round shaped body.

- Energised holding force.

- 11 body sizes.

- Up to 4,890N holding force.

-

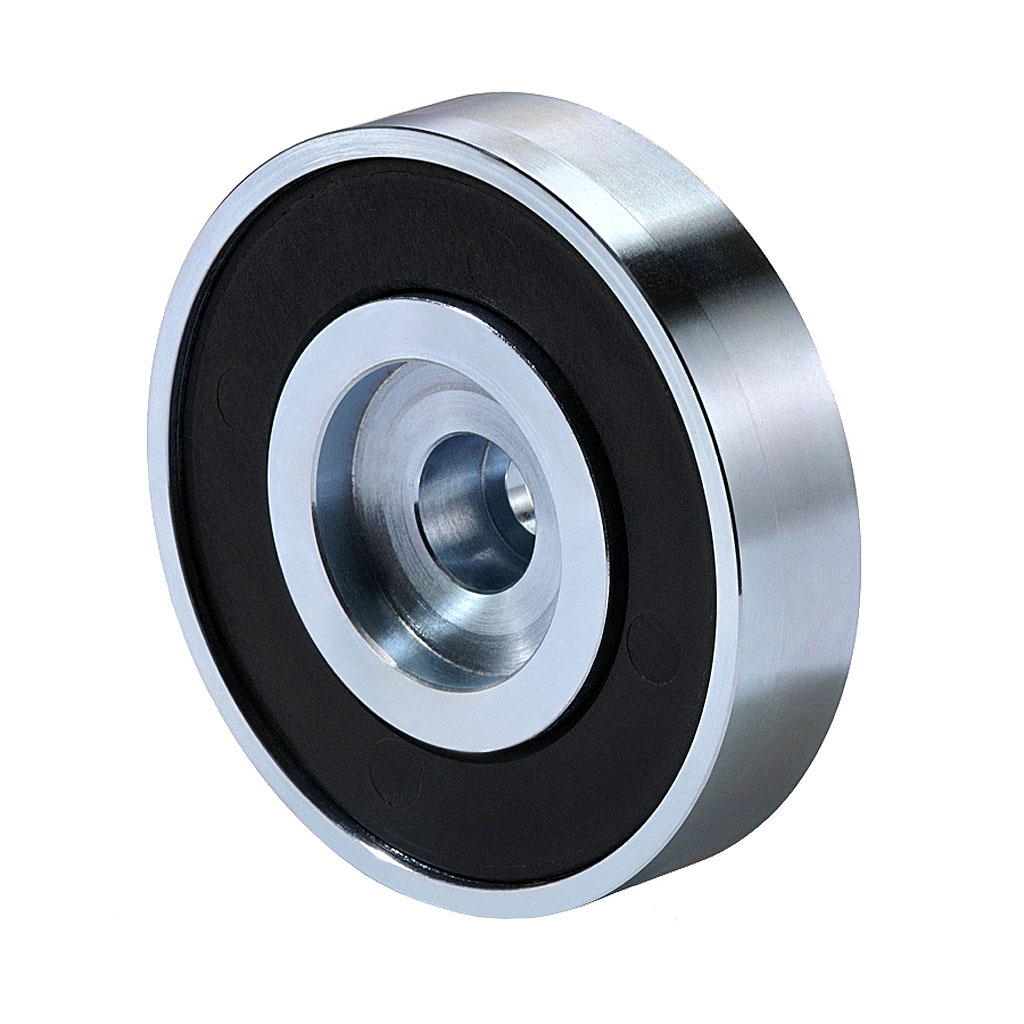

10331 Electro Holding Magnet

- Compact round flat shaped body.

- Energised holding force.

- 3 body sizes.

- Up to 5,000N holding force.

-

10310 Electro Holding Magnet

- Rectangular shaped body.

- Energised holding force.

- 9 bar length sizes.

- Up to 10,400N holding force.

-

01320 / PEM Permanent Holding Magnet

- Compact round shaped body.

- De-energised holding force.

- 12 body sizes.

- Up to 3,500N holding force.

-

01310 Permanent Holding Magnet

- Rectangular shaped body.

- De-energised holding force.

- 2 bar length sizes.

- Up to 1,530N holding force.

Holding magnets do not have moving parts; they attract ferromagnetic material holding it firmly in place with a strong magnetic field.

Holding magnets are suited to applications requiring a fast repetitive operation, eliminating wear and tear that would cause other mechanically operated devices with moving parts to fail.

They manipulate items to ensure the correct location. Conveyor lines use holding solenoids or pick-and-place machines that require a quick, reliable, and robust response in an automation process.

Holding magnets are used within security or safety applications, such as door-holding or entry systems.

Electro-holding magnets come in four designs: round, rectangular, flat, and ring-shaped; the largest achieves up to 30,000N of holding force.

Standard voltage is 24V DC, 100% ED rated with flying leads or plug connection.

The maximum holding force is only reached depending on the materials surface smoothness, the materials thickness, and an air gap of 0mm.

DC holding magnets are divided into two different designs and variants.

- Electro Holding Magnets

Electro-holding magnets consist of a housing and a DC-excited coil. In an energised state, electro-holding magnets hold ferromagnetic workpieces. When de-energised, the workpiece disengages.

The holding system works with a low operating current and is maintenance-free.

- Permanent Holding Magnets

Permanent holding magnets consist of a permanent magnet to hold ferromagnetic workpieces. When energised, the permanent magnet neutralises, and the workpiece disengages.

As a result, these holding magnets are ideal where long holding periods are required and energised for short times only.

In transportation devices, permanent holding magnets are used as safety magnets as loads are held reliably, even in a power failure situation.